Since its founding in 1987, Full Sail Brewing Company has led the pack in terms of sustainable brewing practices, setting an example for other local breweries to follow. Photo courtesy of Full Sail.

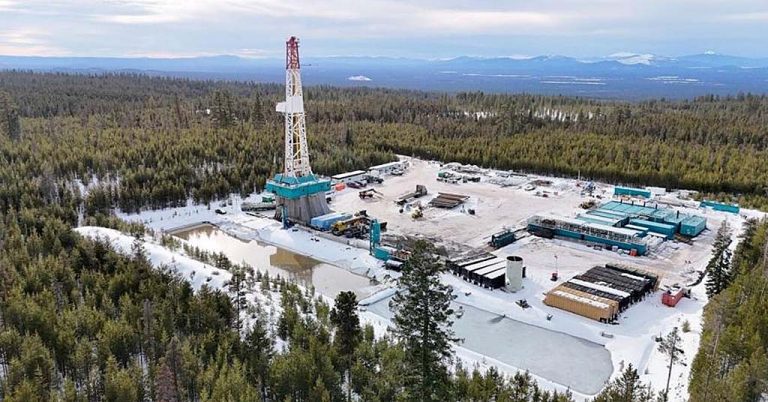

By Will Smith. March 15, 2018. In 1987, the United Nations sponsored Brundtland Report defined sustainable development as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” Coincidentally, 1987 was also the year that the first modern Gorge microbrewery, Full Sail, was established, setting the stage for an explosion of beer culture in the area.

Over the next 31 years, twelve more Gorge breweries popped up, from Washougal to The Dalles, each with their own unique taste and style. By using local ingredients, environmentally friendly waste management practices and recycled equipment, and by fostering deep connections among their local communities, these local breweries share in the spirit of sustainable development that has blossomed alongside this burgeoning beer movement throughout the Gorge.

LOCAL INGREDIENTS

The four main ingredients in beer are water, hops, yeast, and grain. Luckily for local brewers, water in the Gorge is plentiful and, more importantly, it is clean. Sourced from mountain streams, glaciers and springs, it is sought after by bottling companies. Chances are, the water in the beer you are drinking this month was ice on a Mount Hood glacier last month.

Full Sail uses water sourced directly from Mt. Hood, which also serves as a picturesque backdrop to their downtown Hood River location. Photo courtesy of Full Sail.

The second ingredient is a point of pride in the Northwest, a region known worldwide for its hops. From the Willamette Valley 60 miles to the west, to the Yakima Valley 60 miles to the northeast, the majority of hops used by local breweries are often shipped in from less than two hours away. Research shows that 97.8 percent of hops used in the United States are grown in Oregon, Washington and the Idaho panhandle, with the nearby Yakima valley accounting for almost 75% of national hop production alone.

The third ingredient, yeast, is defined in the dictionary as “a microscopic fungus consisting of single oval cells that reproduce by budding—capable of converting sugar into alcohol and carbon dioxide.” Essentially that means that when yeast devours the sugars in the wort, the byproduct gives beer its fizz and its drinkers a buzz. Brewers don?t have to look far for this ingredient either.

Full Sail propagates their own yeast on site, while other breweries look to the microbiologists at Wyeast laboratories, located just north of downtown Odell, OR, who make a wide variety of fermentation products sold nationwide. They have become so popular, in fact, that brewers sometimes need to look elsewhere to obtain their yeast. Aaron Lee, co-owner of Sedition Brewery in The Dalles, says that when Wyeast is too busy they acquire their yeast from Imperial Organic Yeast in Gresham.

Wheat is grown throughout eastern Oregon and Washington. However, much of the grain grown in Wasco County, for example, is either Hard Red or Soft White Winter Wheat. These are predominantly grown for bread and noodles and are often inappropriate for beer. According to Laurie Light of Freebridge, they have done some specialty batches using this grain but mostly acquire a more suitable grain from Eastern Washington.

The variety of grain grown locally isn’t the only limiting factor. Farmers could grow a more beer-friendly offering if they chose, but there are no large scale malters to sell to in the area. Lee noted that there is a malter in Madras, and that Rogue Brewery of Portland has a small-scale malter in Sherman county, but the malting process—heating, drying, and cracking the grain—can be expensive, and some grains they use come from Canada or as far away as Germany.

In addition to the four basic ingredients, many brewers incorporate a wide range of other local additives to satisfy the discerning palate. Nearby cherries make it into your Double Mountain Krieg, farm fresh fruit out of Hood River valley orchards ends up in your Logsdon Flanders style brew, and Solera?s sour beer is aged on local fruits.

You can also find a wide array of local fruits, vegetables and meats across any Gorge brewery’s food menu. Pfriem, for example, has a burger crafted from Dufur-based Shadow Mountain meat, and Walking Man’s vegetarian Banh Mi burger is made with hemp from Tofurkey out of Hood River.

WASTE MANAGEMENT

Sometimes a brewer’s waste is a farmer’s treasure. Full sail takes approximately 1,200 tons of yeast solids and combines it with about 4,100 tons of spent grains to provide more than 5,000 tons of feed to a local dairy farm. Which means that when you drink local milk, you may be enjoying a form of reprocessed local beer as well.

Backwoods provides a local farmer with their spent grain to feed cows, pigs, and chickens that eventually make their way to a farmer’s market near you. A hog farmer outside The Dalles is the lucky recipient of Freebridge’s castaways. The same is true in Parkdale, where Solera’s spent grains benefit another local farmer.

Of course liquid waste must be accounted for as well. Full Sail, taking it one step further, has a water treatment plant on site where they pretreat their waste water before it enters the Hood River treatment plant. The biosolids that result from that process find their way to Dirthugger, a local composting company based in Dallesport. Freebridge also partners with Dirthugger to deliver excess solid biodegradable waste beyond what the local hog farmer needs.

Full Sail employee Francisco Martinez cleans their Meura mash filter, a device that, along with their hot-water recovery system and on-site water treatment plant, has helped the brewery reduce their water usage by about 4.1 million gallons a year. Photo courtesy of Full Sail.

Local entrepreneurs find other unique uses for beer waste. At Backwoods Brewery in Carson, WA, they turn expired beer into bourbon by using it in their distilling process at their sister company, Whiskey Tree Distilling. And according to Jordan Tanasse, Director of Sales and Marketing for Backwoods, a wife of one of the employees uses the spent hops in a beer soap she crafts.

RECYCLED EQUIPMENT

That beer bubbling away in your glass is a product of far more than just the ingredients that go into it. It has flowed through a vast array of tanks, tubes, and machinery before making it to the keg, equipment that all had to come from somewhere.

Half of the equipment that Lee started with at Sedition was used, hand me down, repurposed gear, often found by using a specialty broker out of Portland. Instead of installing a new keg washing system, Sedition uses a system operated by another larger Gorge brewery. This permits a new brewery to save space in its warehouse and focus on the product, while using the established industry in the area to help ease into the first few years in the market.

Double Mountain has a mash tun they acquired from a Colorado brewery. Most of Freebridge’s kegs came out of 10 Barrel Brewery from Bend, while their keg washer and pizza oven recently resided in Double Mountain’s kitchen. The 10-barrel system they operate came from a closed Eugene brewery.

Even the buildings themselves are often recycled, reused and renewed. Full Sail was started in the old Diamond Fruit Cannery, while Freebridge, the first brewery in The Dalles in over 100 years, can be found in the historic Mint building on the east edge of downtown.

Freebridge is also experimenting with a new kind of recyclable plastic keg acquired from the excess supply of local The Dalles winery Sunshine Mill. These ‘PubKegs,’ made by Rehrig, are widely used in Europe but are generally new to the US beer market. Lighter than a metal keg, they use less gas to ship, and can be reused or recycled.

Pfriem ages some of their beers in wine barrels, which adds years to the life of a wine barrel and gives the beer a more complex flavor profile. Photo by Will Smith.

While plastic kegs may be a novelty in the American beer industry, the practice of aging beer in old winery or liquor barrels is well established. Many local breweries barrel age their beer, typically the sours and lambics.

When barrels acquired from a nearby winery are used, the process adds years to the life of a barrel, value to a winery stock room item, and complex new flavors to your brew. Barrel-aged beer from an old Cabernet cask will carry very different flavor notes than one aged in a Chardonnay cask.

The essence and flavor of various liquors can find its way into your beer as well. For example, Everybody’s Brewing uses recycled bourbon and brandy barrels from nearby Clear Creek Distillery.

So drink up, and when you are done with the final piece of beer storing equipment—the can or bottle—make sure to send it to the recycling center (now earning you 10 cents!) or, in pFriem’s case, give it back to the brewery to be reused.

COMMUNITY CONNECTIONS

The Gorge brewery sharing economy is not limited to ingredients and equipment. Personnel, knowledge and experience are shared throughout the industry as well.

As the oldest Gorge brewery, Full Sail in Hood River has provided fertile training grounds for the local industry. Several of their early brewers went on to found or become involved with neighboring breweries such as pFriem, Double Mountain and Big Horse Brewing.

A non-profit organization called ‘Breweries in the Gorge’ was formed recently as a partnership amongst local brewers. By sharing marketing, ideas, and space in local events (Holiday Hangover, Zwickelmania, and Hopsfest, to name a few), and by creating a forum for brewers to work together, the organization helps to advance brewing in the Gorge as a sustainable industry.

But breweries don’t just support each other. They are also active in their communities.

Thunder Island, possibly the most deeply affected brewery by last September’s Eagle Creek Fire, recently established a campaign to fund local fire departments, raising nearly $25,000. Likewise, Double Mountain regularly hosts auctions and events in its taproom for local fundraising efforts.

On the Washington side, Walking Man Brewery hosted it’s 15th annual Hoptoberfest last fall, a “community event that began with a philanthropic purpose,” says Bob Craig, founder and co-owner of the establishment. The most recent recipient of the proceeds was the Stevenson Fire Association.

From source to savor, the ethics of environmentalism run deep along the Columbia. So grab a ‘Breweries in the Gorge’ passport and make the rounds this spring to taste the full range of sustainably delicious Gorge beers.

Great article! So glad to hear that there is good leadership and community based effort among gore brewers to advance sustainable practices. Increased emphasis on locally sourced products brings brew craft closer to expressing a true and distinctive terroir in their products. The region you are describing has the greatest potential to realize something like “estate” beers

Most enjoyable article! There is one thing that i’m curious about– not one word about Barley, which is far and away the most common grain used for mashing. I have seen fields of Barley growing south of The Dalles, tho i have no idea how much “local” Barley is used by local breweries. Perhaps an oversight?

I got this site from my buddy who informed me regarding this web page and at where to buy viagra over the counter moment this time I am visiting this web site and reading very informative posts at this time.