Photo: The former aluminum plant main entrance and water tower in The Dalles.

By Susanne Wright. Oct. 23, 2017. My editor asked me to attend a public DEQ meeting in The Dalles. She was curious. Something about a permit modification at the old Martin Marietta Aluminum site. She sent along this cryptic email.

Notice of Class II Permit Modification Request and Notice of Temporary Authorization Request. This is a courtesy posting by the Department of Environmental Quality for Lockheed Martin Corporation.

The name, Lockheed Martin, a major defense contractor, caught my attention. Why would Lockheed Martin apply for a ‘permit modification request’ for an aluminum plant long closed? Lockheed Corporation, I learned, merged with Martin Marietta, which operated an aluminum plant in The Dalles.

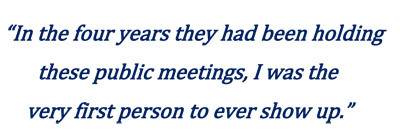

I showed up to the meeting with pen and paper, a recording device, and questions. The three officials looked at me in surprised silence. Good manners kicked in and they bolted up to shake my hand. Fredrick Moore, permit writer for Oregon Department of Environmental Quality introduced himself, and told me that in four years of public meetings, I was the first person ever to show up.

I, Jane-Q-Public, sat down with Moore, Liaht Rosenstein, a Lockheed Martin environmental remediation analyst, and engineering support contractor, Scott Adamek of CDM Smith. The job titles gave me no idea what the meeting was about. Rosenstein started by telling me that I could not record the meeting. And so I poised pen, old school style, and fired off my first question.

What is this meeting about?

The answer came with an engineer’s efficiency. Rosenstein handed me a large poster-size aerial photo of the Martin-Marietta Aluminum Company site. She pointed out the exact locations of a CERCLA (Comprehensive Environmental Response, Compensation, and Liability Act) landfill and scrubber sludge ponds. CERCLA? Scrubber sludge ponds? She said this meeting was to go over their upgrade to the hazardous waste containment system. Lockheed installed among other things, new leachate monitoring technology. After a successful testing period, she said, the company applied for permits to make the changes permanent. Leachate?

Here my all-too-brief pre-meeting research into aluminum production saved me; otherwise my brain might have clenched listening to their sanitized, technical engineering terms for what is an environmental disaster.

Map of the former aluminum plant site just south of the Columbia River in The Dalles. Photo: U.S. EPA

Allow me to explain. Aluminum is a remarkable material. Strong, recyclable, and corrosion proof. It can be cut, shaped, polished and made into countless things. Whether we realize it or not, we are all dependent on it. Electrical power lines, intricate computer components, kitchen appliances, and airplanes are a few of the things made from aluminum.

Unless you live in a cave and ride a horse for transport, you are hooked on the stuff. But like many industrial man-made materials, aluminum production leaves behind deadly chemical by-products.

At The Dalles aluminum plant, cyanide, arsenic, PAHs, cathode, and asbestos waste was stored in raw landfills with no protective bottom membrane. Significant amounts of toxic leachate (contaminated liquids) contaminated soil and the area aquifer. This continued unabated for twenty-six years until the formation of the Environmental Protection Agency in 1970. Created to protect human and environmental health, the EPA placed the 350-acre Martin-Marietta plant on a Superfund clean-up list.

Per Superfund clean-up recommendations, 200,000 cubic yards of hazardous waste, including the razed plant buildings, was dumped into a 15-acre onsite landfill with no bottom liner and capped off with mounded soil. Leachate was collected and treated with sludge ponds. A second capped 15-acre landfill was filled with 64, 670 cubic yards of cathode waste (spent pot liners) and contains toxic sludge and soil. They abandoned onsite wells and protected nearby homes with wells from possible waste contamination by connecting them to the city of The Dalles water supply system.

The plant was removed from the Superfund list in 1986 upon completion of requirements. The EPA ruled that Martin-Marietta be held responsible for ongoing operations and monitoring for leaks of chemicals into soil, water or air. Lockheed Martin has upgraded the systems as technology allowed. Their most recent upgrade, and the reason for the public meeting, was primarily focused on upgrading the monitoring method to computer systems for data collection eliminating the need for human contact with toxic substances.

How long will this site be toxic? I asked.

Adamek responded, “It is unknown.” No one knows how long the material will be toxic, not even Lockheed Martin Corporation, who is tasked with containing and monitoring the waste.

Onsite landfill with no bottom liner and capped off with mounded soil

Why was there no protective liner placed beneath the toxic waste material? Lockheed Martin avoided any real explanation, offering only that it was too hazardous to remove the material or truck the material to another site.

I left the meeting impressed with the earnestness of Lockheed Martin and CDM Smith engineers. Bright and dedicated, they are proud of the success of their recent upgrade. I was equally disturbed by the lethal poison buried in the womb of the Columbia River Gorge.

Heavy industry and toxic waste are often one in the same. A city tolerates one for the sake of the other, as was the case with this aluminum plant in The Dalles. One cannot discount the importance of Martin-Marietta to the region’s economy, or the suffering when it shuttered in 1984.

Aluminum production has always been a boom and bust industry. Northwest operations died off from a combination of rising hydroelectricity prices and competition from foreign markets. The plant closure sparked a regional economic depression. Displaced aluminum plant employees either retired or found work elsewhere. Suffering a loss of identity, The Dalles eventually rebounded, creating a more secure, broader-based economy. What will not rebound, what will not heal, is the land itself. For how many years? Centuries?

I wondered what area residents knew in the early years of the plant’s operation. Were they aware the area had been sacrificed, and placed off limits, possibly forever? Given the times, was it even a cause of concern, accepted as a standard method to dispose of unwanted material? Questions that speak to the way humans perceive immediate verses long-term risks.

Psychologists argue that humans are exquisitely designed to respond to immediate short-term problems such as running from a snorting bull, but we are not good at probable, but more distant dangers of burying deadly toxic waste in the ground.

Scrubber sludge ponds behind fencing at the site

Examples of this are found up and down the Gorge. During the construction of the Bonneville Dam the U.S. Army Corp of Engineers dumped electrical components containing PCBs into landfills on Bradford Island, a historic fishing site of the Yakima Nation, and into the Columbia River. Until 2003 Columbia Gorge Aluminum, (CGA) approximately one mile northeast of the John Day Dam, on the north side of the Columbia River, buried hazardous chemicals including (but not limited to) PAHs and metals, including arsenic, cadmium, and mercury, contaminating both soil and groundwater. Two aquifers lie beneath this upland site with groundwater generally flowing to the south towards the Columbia River, possibly carrying toxic waste, a cause of grave concern.

All of which brings me back to my meeting with the two young engineers. They had yet to be born when Martin-Marietta was busy churning out aluminum. Yet these two young adults are the now handlers of the toxic site left behind. Waste maintenance will span long past their lifetimes. What happens if Lockheed Martin Corporation ceases to exist? Success is never guaranteed. Who will take their place?

As for the future of the Martin-Marietta Remediation Project, Rosenstein explains, “What’s next after we complete the treatment plant upgrades: continued treatment of the landfill leachate with ion exchange (IX) resin, monitoring of groundwater, site inspections and maintenance when necessary.”

“Environmental pollution is an incurable disease. It can only be prevented.” -Barry Commoner

RELATED POSTS

Hardwood furniture possesses one thing very natural about it.

There is this sense of coziness, of nature and also of beauty that can be

be found in hardwood household furniture. Wood is actually

born from the planet.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now

each time a comment is added I get several e-mails with the same comment.

Is there any way you can remove me from that service?

Bless you!