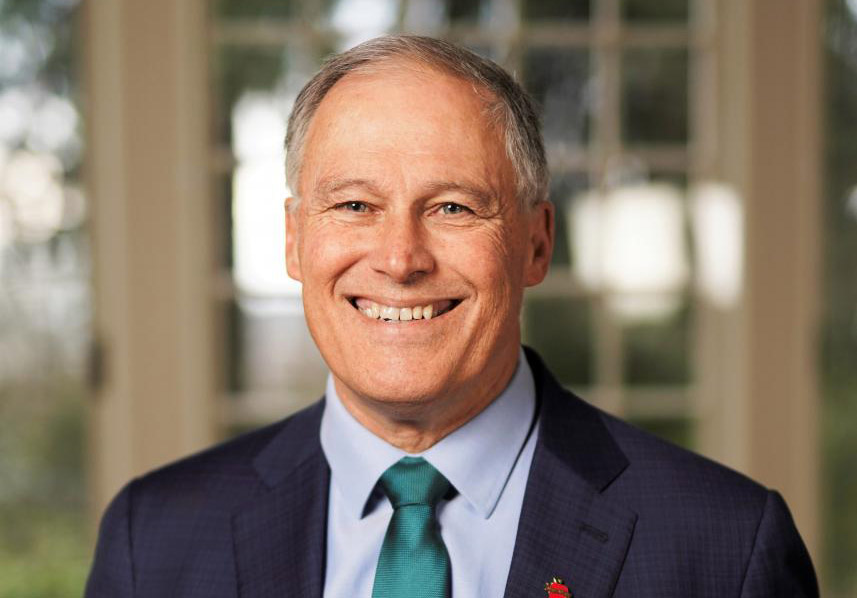

The job is massive. Parts weighing up to 50,000 pounds are cut apart with acetylene torches then shipped to Portland

Huge burn: It’s not easy dismantling a piece of machinery that weighs as much as an adult humpback whale. Photo: Dick Mason/The Observer

By Dick Mason, The Observer. October 3, 2022. Winds of change are generating excitement at B&K Auto Salvage and Recycling in La Grande, Ore.

The gusts are blowing in from wind farms in Arlington, 125 miles to the west, in the form of semi-trucks carrying parts from wind turbines that have been shut down due to declining condition after decades of use.

La Grande’s B&K has contracted with a wind farm-related organization to cut up wind turbine parts and send the metal to Portland for recycling.

Cutting wind turbine parts, which consist of gearboxes, main shafts and blade hubs, is difficult because of their size, according to Danny Huddleston, recycling manager at B&K.

“The gearboxes weigh 45,000 pounds, and the main shafts and the blade hubs weigh 50,000 pounds,” he says.

The metal wind turbine parts are cut with acetylene torches by a crew from an Indiana-based company called Premier Scrap Processing working with B&K.

B&K began receiving shipments from wind farms in the Arlington area on Sept. 1. As of Sept. 20, it had received 141 shipments from semi-trucks.

“We usually get 10 to 14 shipments a day,” says Huddleston.

Attention getter

On some occasions as many as three semi-trucks have arrived at B&K at about the same time, causing passing motorists to do double takes.

Huddleston says he enjoys explaining the process.

“This is definitely turning heads. People will say, ‘What is happening?’ It is nuts,” he says. “It is pretty neat to get stop-ins like this.”

Each truck carries only a gearbox, main shaft or blade hub. Trucks can’t transport more than one item at a time because of state and federal weight laws.

[perfectpullquote align=”full” bordertop=”false” cite=”” link=”” color=”” class=”” size=””]The company wants all the parts cut up before winter.[/perfectpullquote]

Once a truck arrives at B&K, a crane with a hook lifts the part and lowers it to the ground.

B&K is never sent aging blades of old wind turbines because they’re made of balsa wood, something the La Grande company doesn’t handle, according to Huddleston.

The gearboxes, main shafts and blade hubs B&K receives are all 20 to 25 years old.

Huddleston says that when the wind turbines were installed many people believed they would last about 15 years. Their longevity was probably underrated, he says, because there were a lot of unknowns 25 years ago.

“It was not known how much the turbines would be turning,” he says.

Scrap sent to Portland company

To create room for the wind turbine parts, the company removed about 100 automobiles from its storage yard. They were crushed and sent out for recycling.

B&K is working with other area companies to make sure wind turbine parts are recycled.

Huddleston says the company’s goal is to have all of the metal for the wind turbine parts cut up before winter hits because it’s harder to work then. One of the biggest challenges winter poses is the deep snow and mud it creates, which makes it easy to lose things that don’t turn up again until the spring.

The wind turbine metal parts B&K is cutting up are being sent to Schnitzer Steel in Portland. Huddleston says the metal will eventually be melted down as part of the recycling process.

Since Sept.1, B&K has sent two truckloads carrying 60,000-68,000 pounds of cut-up wind turbine metal to Schnitzer Steel.

Huddleston hopes B&K can continue to help recycle metal from old wind turbines.

“It is work. This keeps everybody busy,” he says, adding that it’s fascinating work, as well.